This 230ml PE bottle with a pump head is a perfect choice for both aesthetics an...

Laundry Detergent PE Bottles Manufacturers

-

-

450ml chemical-resistant PE bottle

450ml chemical-resistant PE bottleThis 450ml chemical-resistant PE bottle is ideal for detergent packaging. Made o...

-

1000ml transparent chemical-resistant PET bottle

1000ml transparent chemical-resistant PET bottleThis 1000ml transparent, chemical-resistant PET bottle is ideal for filling dete...

-

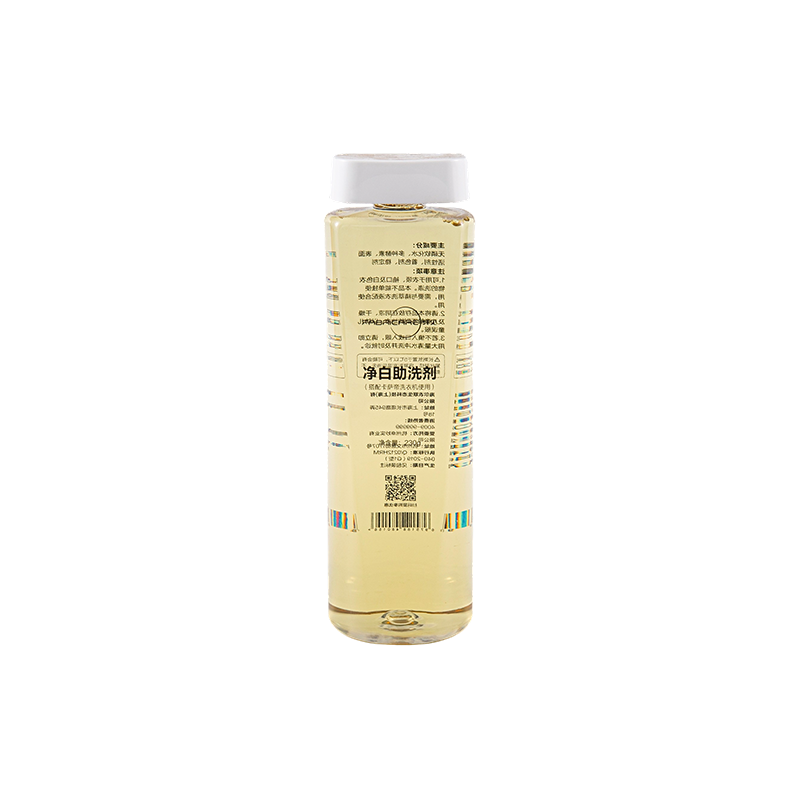

300ml transparent visible laundry detergent PET bottle

300ml transparent visible laundry detergent PET bottleThis 300ml transparent visible laundry detergent PET bottle, built with practica...

-

1000ml low temperature resistant laundry detergent PE bottle

1000ml low temperature resistant laundry detergent PE bottleThis 1000ml low-temperature resistant laundry detergent PE bottle is ideal for p...

-

230ml chemical-resistant PET bottle

230ml chemical-resistant PET bottleCrafted for reliability and versatility, the 230ml PET chemical-resistant transp...

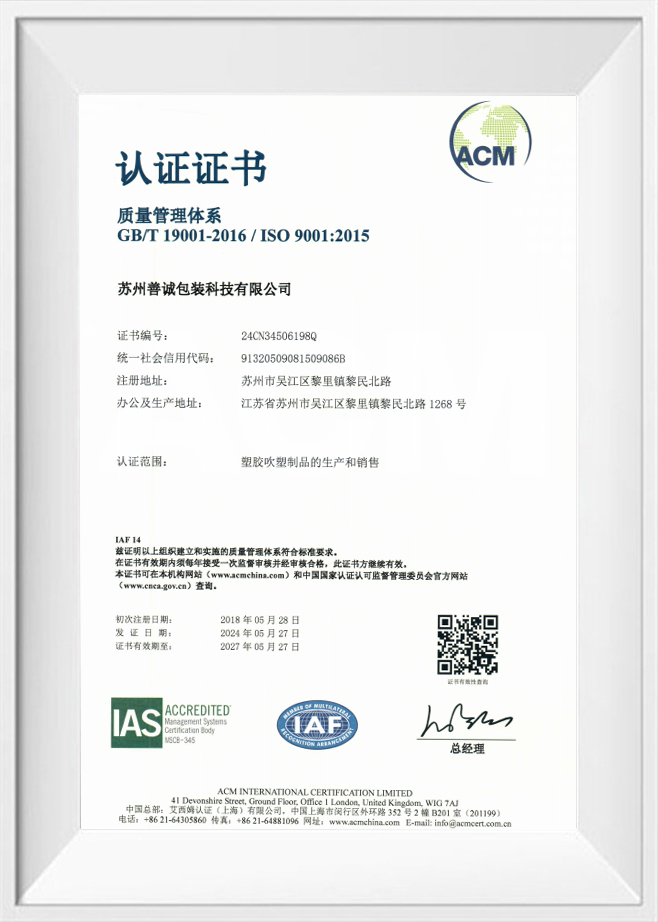

Suzhou Brotherpacking Plastic Co., Ltd. , established in 2013, is a professional manufacturer specializing in custom plastic packaging for the daily chemical industry. As Laundry Detergent Bottles Manufacturers and Laundry Detergent Plastic Bottles Factory, with a fully integrated production system — including in-house mold design, product development, injection and blow molding, labeling, and final assembly — we serve a wide range of packaging needs for skincare, haircare, body care, and home care brands. Our facility includes an independent mold workshop, high-speed CNC machines, over 50 injection machines and 30+ blow molding machines, supporting multiple material types such as PE, PP, PET, and PETG. Products are exported across Europe, the Americas, and Southeast Asia. Support Custom PE/PET Laundry Detergent Bottles Packaging. At BrotherPack, we uphold the spirit of craftsmanship and continuous improvement, delivering high-quality, flexible, and scalable packaging solutions trusted by global clients.

-

25+

Years of Industry Experience

-

20000㎡

Manufacturing Facility

-

150+

Skilled Employees

-

100+

Advanced Production Machines

-

The packaging industry's choice of materials for laundry detergent bottles is far from arbitrary. Walk down any supermarket aisle and you'll notice that the vast majority of laundry detergent containers are made from polyethylene (PE) rather than polyethylene terephthalate (PET), despite PET's popul...

READ MORE -

Cosmetic bottle sizes span a wide spectrum, typically ranging from miniature 5ml containers to generous 500ml bottles, each serving distinct purposes in the skin care product packaging ecosystem. The most prevalent size categories include travel-sized containers (5ml-15ml), sample and trial sizes (1...

READ MORE -

Introduction to the 110ml Wide-Mouth PP Jar The 110ml wide-mouth PP jar is a compact plastic packaging container widely used across food, pharmaceutical, cosmetic, and industrial sectors. Its moderate capacity and wide opening make it suitable for products that require easy filling, scooping, or dis...

READ MORE

Do Suzhou Brotherpacking Plastic Co., Ltd.'s Laundry Detergent PE Bottles have UV protection to prevent discoloration?

When it comes to premium laundry detergent packaging, durability and product integrity are as important as aesthetics. Laundry Detergent PE Bottles face unique challenges: exposure to sunlight, fluctuating temperatures, and long-term storage can all compromise the quality of both the container and its contents. One critical consideration is UV protection, which prevents discoloration, brittleness, and chemical degradation of the bottle over time.

Understanding UV Exposure and Its Impact

Polyethylene (PE), widely used for detergent bottles, is naturally prone to photodegradation when exposed to ultraviolet light. Without proper protection, bottles may yellow, warp, or lose structural integrity, affecting both the appearance and safety of the product. For manufacturers and brands, this is more than cosmetic; it’s a potential threat to customer trust and shelf appeal.

UV-stabilized PE incorporates additives that absorb or block ultraviolet rays, maintaining the bottle’s original color and mechanical strength. These stabilizers work by intercepting harmful UV photons before they break down polymer chains, ensuring the detergent remains secure and visually appealing for the duration of its shelf life.

BrotherPack’s Approach to UV-Protected Bottles

Suzhou Brotherpacking Plastic Co., Ltd., established in 2013, is a professional manufacturer specializing in custom plastic packaging for the daily chemical industry. As leading Laundry Detergent Bottles Manufacturers and a Laundry Detergent Plastic Bottles Factory, BrotherPack combines craftsmanship with cutting-edge technology to produce packaging that withstands environmental challenges, including UV exposure.

With a fully integrated production system—covering in-house mold design, product development, injection and blow molding, labeling, and final assembly—BrotherPack ensures that each PE bottle meets exacting standards. The facility includes an independent mold workshop, high-speed CNC machines, over 50 injection machines, and 30+ blow molding machines, supporting diverse materials such as PE, PP, PET, and PETG.

When producing Laundry Detergent Plastic Bottles, UV stabilizers can be incorporated into the resin during molding. This proactive measure prevents discoloration, extends the bottle’s life, and safeguards the detergent inside. Additionally, BrotherPack’s expertise in material selection allows for customization to match brand aesthetics without compromising durability.

Benefits of UV-Protected Laundry Detergent Bottles

- Preserved Visual Appeal – Maintains original color and clarity over time, enhancing shelf presentation.

- Enhanced Structural Integrity – Prevents brittleness and cracking caused by prolonged UV exposure.

- Prolonged Product Safety – Shields detergents from chemical degradation triggered by light.

- Brand Reliability – Demonstrates commitment to quality and longevity, fostering consumer trust.

Conclusion

For brands seeking robust, high-performance packaging, BrotherPack’s Laundry Detergent PE Bottles with UV protection offer a reliable solution. By integrating advanced UV stabilizers and leveraging a fully integrated manufacturing system, Suzhou Brotherpacking Plastic Co., Ltd. ensures that each bottle retains its structural integrity, appearance, and safety over time.

In an industry where presentation and product protection go hand in hand, UV-protected PE bottles are not just an option—they are a strategic investment in quality and brand reputation.

English

English Español

Español