This 700ml PE bottle of floor cleaner features a sleek white body and a striking...

Disinfectant Spray Bottle Manufacturers

-

-

500ml PE disinfectant bottle

500ml PE disinfectant bottleThis 500ml PE disinfectant bottle is designed specifically for daily chemical di...

-

500ml PE spray bottle

500ml PE spray bottleThis 500ml PE spray bottle is made from food-grade materials, ensuring safety fr...

-

400ml white simplicity spray PE bottle

400ml white simplicity spray PE bottleThis 400ml white simplicity spray PE bottle features a practical design that mee...

-

500ml tough material spray bottle

500ml tough material spray bottleThis 500ml tough material spray bottle from PE is the ideal choice for both dura...

-

500ml simple and elegant PE spray bottle

500ml simple and elegant PE spray bottleIntroducing the 500ml simple and elegant PE spray bottle, a practical choice for...

-

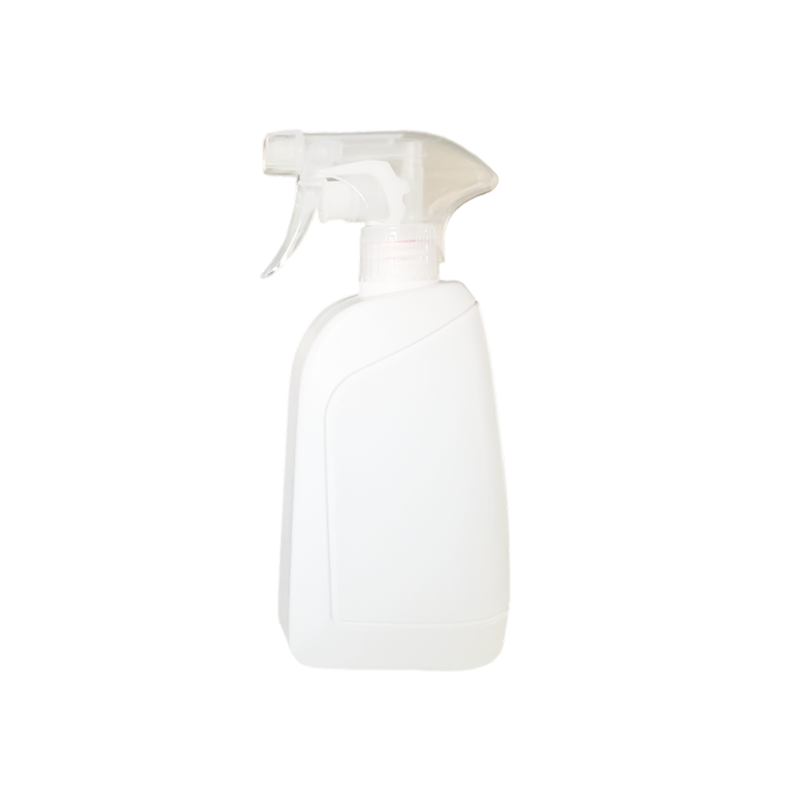

500ml acid and alkali resistant disinfectant PE square bottle

500ml acid and alkali resistant disinfectant PE square bottleThe 500ml acid and alkali-resistant disinfectant PE square bottle is a practical...

-

300ml drop-resistant and pressure-resistant disinfectant PE round bottle

300ml drop-resistant and pressure-resistant disinfectant PE round bottleThis 300ml drop-resistant and pressure-resistant PE round bottle is designed for...

Suzhou Brotherpacking Plastic Co., Ltd. , established in 2013, is a professional manufacturer specializing in custom plastic packaging for the daily chemical industry. As Disinfectant Spray Bottle Manufacturers and PE Spray Bottle Factory, with a fully integrated production system — including in-house mold design, product development, injection and blow molding, labeling, and final assembly — we serve a wide range of packaging needs for skincare, haircare, body care, and home care brands. Our facility includes an independent mold workshop, high-speed CNC machines, over 50 injection machines and 30+ blow molding machines, supporting multiple material types such as PE, PP, PET, and PETG. Products are exported across Europe, the Americas, and Southeast Asia. Support Custom PE Spray Bottle for Disinfectant Packaging. At BrotherPack, we uphold the spirit of craftsmanship and continuous improvement, delivering high-quality, flexible, and scalable packaging solutions trusted by global clients.

-

25+

Years of Industry Experience

-

20000㎡

Manufacturing Facility

-

150+

Skilled Employees

-

100+

Advanced Production Machines

-

The packaging industry's choice of materials for laundry detergent bottles is far from arbitrary. Walk down any supermarket aisle and you'll notice that the vast majority of laundry detergent containers are made from polyethylene (PE) rather than polyethylene terephthalate (PET), despite PET's popul...

READ MORE -

Cosmetic bottle sizes span a wide spectrum, typically ranging from miniature 5ml containers to generous 500ml bottles, each serving distinct purposes in the skin care product packaging ecosystem. The most prevalent size categories include travel-sized containers (5ml-15ml), sample and trial sizes (1...

READ MORE -

Introduction to the 110ml Wide-Mouth PP Jar The 110ml wide-mouth PP jar is a compact plastic packaging container widely used across food, pharmaceutical, cosmetic, and industrial sectors. Its moderate capacity and wide opening make it suitable for products that require easy filling, scooping, or dis...

READ MORE

How Durable Are Suzhou Brotherpacking Plastic Co., Ltd.'s Disinfectant PE Spray Bottles Under Frequent Use?

In the competitive world of daily chemical packaging, durability is not just a preference—it’s a necessity. For brands seeking reliable and resilient solutions, Suzhou Brotherpacking Plastic Co., Ltd. has emerged as a benchmark in custom plastic packaging, particularly in the realm of disinfectant PE spray bottles. With a decade of expertise, Brotherpack seamlessly combines innovative engineering with meticulous craftsmanship to meet the rigorous demands of frequent usage.

Precision Engineering for Unmatched Strength

Durability begins at the design stage. Brotherpack’s fully integrated production system includes in-house mold design and product development, ensuring that every PE spray bottle is engineered to withstand repetitive handling and high-frequency use. By leveraging high-speed CNC machines and a dedicated mold workshop, the company achieves tight tolerances that minimize wear and tear. The bottles retain their form and functionality even under the rigorous stresses of daily disinfectant application.

Material Integrity and Performance

Suzhou Brotherpacking Plastic Co., Ltd. offers a spectrum of material options, including PE, PP, PET, and PETG, allowing each bottle to be tailored to its intended application. Polyethylene (PE), the primary material for these disinfectant spray bottles, is celebrated for its flexibility, chemical resistance, and impact strength. This ensures the bottles remain intact during drops, squeezes, or repeated spray cycles. High-quality polymers, combined with expert blow molding techniques, reduce the risk of leaks, cracks, or deformation over time.

Advanced Manufacturing Capabilities

Durability is further reinforced by Brotherpack’s impressive manufacturing capacity: over 50 injection machines and 30+ blow molding machines facilitate consistent production quality at scale. This infrastructure supports complex bottle geometries and customizable designs without compromising structural integrity. Each bottle undergoes rigorous assembly and labeling processes to maintain uniformity, making them reliable companions for high-demand environments like hospitals, commercial cleaning, and industrial sanitation.

Ergonomics and Functional Longevity

Durable design extends beyond material strength. Brotherpack’s PE Spray Bottles are crafted for ergonomic handling, optimizing comfort during repetitive use. Sprayer mechanisms are precision-engineered to sustain thousands of actuations without clogging or leakage. The combination of robust bottle bodies with resilient spray pumps ensures longevity while maintaining consistent performance—critical for businesses that rely on reliability during high-volume cleaning operations.

Global Standards and Consistent Quality

With a client base spanning Europe, the Americas, and Southeast Asia, Brotherpack’s commitment to quality is validated on a global scale. Every disinfectant PE spray bottle is the result of a philosophy rooted in continuous improvement and craftsmanship. The company’s rigorous quality control procedures and dedication to innovation mean that each unit is not only durable but also adaptable, meeting the evolving needs of daily chemical brands worldwide.

Conclusion

When assessing durability, Suzhou Brotherpacking Plastic Co., Ltd.’s Disinfectant Spray Bottles excel through a combination of high-grade materials, precision engineering, and advanced manufacturing. Frequent use—whether in commercial, industrial, or home environments—poses little threat to their structural integrity or functional performance. For brands seeking packaging that balances resilience, aesthetics, and functionality, Brotherpack delivers solutions designed to endure.

The result is more than a bottle—it is a durable, reliable tool engineered to withstand the rigors of frequent use, ensuring that disinfectants reach their full potential every time they are applied.

English

English Español

Español